Products

Pipeline Products machine shop’s home is based out of League City Texas, and is run strictly on the manual process where everything is handmade! We house only manual-run machines and no CNC! Pipeline Products plans to get into the CNC machining process in the future to allow us to run more oversized orders of parts for bigger budgets. As of now all the machines we run and operate are based on the manual process. All of our employees are skilled in the manual trade of working with metals. Everything we manufacture is right here in the USA! The only thing we outsource is the lab testing on the products we produce. Our machine shop specializes in the manufacturing or reconditioning of parts/tools that are used during the Hot Tapping Process. We are also a general machine shop here to service any special projects or needs that may arise.

Manual Machining Principles

Manual machines are controlled by hand and run by employees that are skilled in the trade of operating such a machine. This would include operating traditional machines such as bandsaws, drill presses, grinders, mills, welders, plasma cutters, and lathes. Utilizing such manual machines, machinists can use their creativity to create a vast number of prototyping items for various purposes. Manual machining takes more time and more attention to perform any function when compared with CNC machining that’s controlled by automation or a computer. But when you compare CNC against the manual process when running a small run of parts, prototype work, or one-off parts it turns out to be more cost-effective., pulvinar dapibus leo.

The advantages of manual run machining over CNC

- Less costly for small production of parts as well as one-off parts The pros to a manual shop over CNC are that manual machines are great for making quick runs of small parts, and one-off parts, as well as creating new designs for tools for R&D (Research and Development), or any type of prototype work. Manual machining can also be utilized to manufacture plastic and metal parts to achieve the same end.

- Good choice for metal designs or simple shapes This makes the manual machining process the go-to for small operations, parts fabrication, research and development, and reconditioning of tools or parts. The conventional manual machining method is recommended for creating simple metal shapes or designs as it proves to be less costly than other methods. With careful cutting, you can get high accuracy on a manual lathe over the CNC process. Even tho both processes are extremely accurate, the manual process is more cost-effective when it comes to these types of projects.

The advantages of manual run machining over CNC

- CNC machines are a lot more expensive to run than manually operated machines. This means it’s going to take a bigger budget to get anything manufactured. This makes CNC machines the go-to for larger orders of parts for companies with a bigger budget in mind. While we don’t house any CNC machines at our shop as of yet we plan to in the future

- The CNC machine operator does not require knowledge of the machining trade as the manual operator does. The only needs of the operator are basic training and skills, just enough to supervise several machines that are run by a computer. So the manual machine operator is by far superior when it comes to the knowledge of the machining trade and problem-solving skills when it comes to the art of working with metal to create new tools and designs. Making the manual processes the choice for prototype work for research and development, quick runs for small orders of parts, as well as reconditioning of tools or machines. As you can see that a manual shop has its pros over a machine shop that is run by computers and people with just enough skills to just keep the machine running. So when you have any type of manufacturing needs for small runs of parts, reconditioning of parts or machines that are utilized in the Hot Tapping procedures, or maybe you are looking to design a new prototype for research and development, Or you just need a general machine shop in Houston TX for any special projects or needs that may arise, Pipeline Products has got you covered with a well-rounded staff that excels in the machine shop trade! Reach out today to inquire about our world-class products and services!

Our Product

HOT TAP CUTTERS

Pipeline Products offers a range of service’s when it comes to your shell cutters. Not only do we manufacture new cutters but we also re sharpen them as well. Normally re sharpening includes charting of each cutter for recored keeping as well as traceability. We offer several types of teeth including M-48 tool steel, C-2 carbide which are the industry standard or any special material when requested. Damaged teeth pockets are repaired as well (welded and machined) and in most cases we can straighten out warped back with in tolerance. Liability, today Hot Tapping is pushing the extreme limits, larger sizes, higher pressures,higher temperatures, exotic metals and sub sea taps up to 250 ft plus. Both machines and tooling are reaching new limits, with this in mind companies can’t run the risk of a tooth separating from the cutter.

Read MoreThis is why Pipeline Products has gone to the extreme to keep up with the latest technology. We use state of the art welding (silver soldering) when mounting the teeth to the cutter shell. Our welding is Laboratory Tested!! The weld is only as good as the tooth pocket. We will not silver solder a new tooth into a damaged pocket, just another step we have taken in assuring you the customer that we are giving you the best quality work we offer.

PILOT DRILLS

Pipeline Products manufactures pilots of many sizes and styles to fit any brand of Tapping machine. Along with manufacturing we aslo repair or recondition pilots as well. We use the same M-48 tool steel and C-2 carbide as we do in our cutters. Just like the cutters we offer a broad range of pilots from the standard T.D Wiliamson style to any other special requested pilot you may need for the job. Multi U-Wire pilots are also offered for high flow applications if needed. A standard pilot will come with a silver soldered tip but we also offer pilots to accommodate the removable spade tips per the customers request.

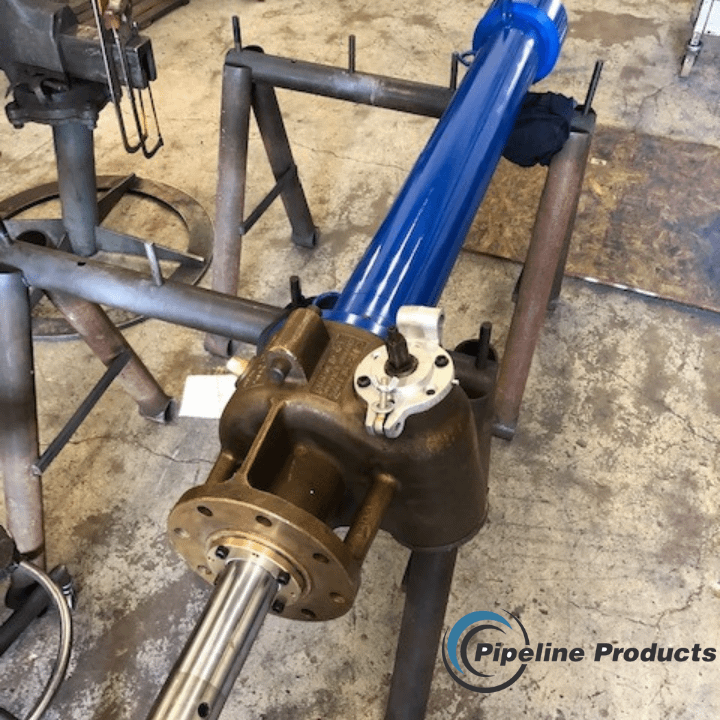

CUTTER HOLDERS

Pipeline Products offers a range of cutter holders and completion plug holders to fit most machines from the standard T.D Williamson style , Mueller, and A.P Smith. Along with the industry standard cutters we also offer special designed holders per the customers request. Our standard holders for the smaller machines in the 1.25″ thru 4.5″ range come with pilot already fixed to the holder. We also offer the smaller holders with removable pilots drills depending on style the customer chooses.

SPECIAL TOOLING

Pipeline Products is here to help you with any special projects that arise. We house several manual machines which lets us manufacture small runs of parts with a quick turn around. Extended drills, twist drills, drive rings, pilot boss’s, pivoting head’s, drive collars, packing wrench’s, spanner wrench’s, swivel handles, spade holders, boring bars and measuring rods just to name a few of the items we offer. When you need it we are here to help.

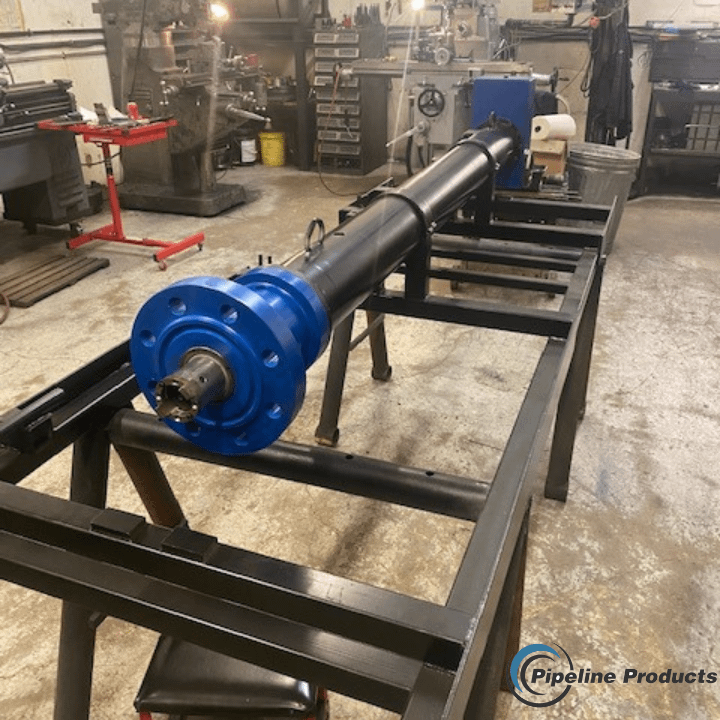

EQUIPMENT REPAIRS AND MODIFICATIONS

We all know everything has a life, and tapping equipment is no different. These machines see a lot of beating and wear and tear, and most can be repaired when damaged. Boring bars seem to take the majority of the abuse causing drive rings to break, broken screws, rounded of hex drives to gaulded and flaking chrome. Pipeline Products offers repairs on your equipment, many times its more feasible to repair than it is to replace due to high costs of OEM parts. So when a machine is down and not being used we can help you get it back online as quick as possible. Pipeline Products has also extended C-1 tapping machines and beefed up the torque tubes to handle larger cuts, and we have manufactured a few of the largest tapping machines in circulation today.

DIAMOND CUTTERS

At Pipeline Products we have recently expanded our services to help with the amount of requests we have received to do diamond cutters. Just as the standard hot tap cutters we now offer manufacturing of multiple style diamond core bits as well as hot tap cutters equipped with diamond segments for the municipality and concrete industry. We offer the standard removal of old worn out diamond segments and replacing of them with new ones. Any size cutter you may have we have the capability to recondition it. Pipeline Products is ready to help you with any special cutter you need designed for the job, we can design a shell cutter to any machine you desire per customers request. We are happy to have expanded our services to help with the diamond cutter market and hope we can help you the customer out as well.

GET IN TOUCH

Please fill out the form below to contact us directly.

We will respond to all requests within 1 business day or less.